19:49

Nitride films are ubiquitous in their use as hard, wear-resistant coatings. In this work, we help contribute to a scale-bridging model, helping build understanding of how initial plasma parameters affect the mechanical properties of the final coating system. To this end, we study the effect of transition metal species and oxygen content in transition metal aluminium (oxy)nitride coatings.

Fracture toughness measurements are made using micro-cantilever bending tests, showing a strong correlation between elastic modulus and toughness. These tests are extended up to elevated temperatures to s...

49:59

The analysis of deformation and failure mechanisms in small-scale devices and thin films is a critical issue, not yet solved. In this presentation, we describe recent advances and developments for the measurement of fracture toughness at small scales by the use of nanoindentation-based methods, including beam-bending methods and micro-pillar splitting. A critical comparison of the techniques is made, by testing a selected group of bulk and thin film materials. Additionally, the extension of the pillar splitting method to the use with different sharp indenters (from Berkovich to cube-corner)...

08:56

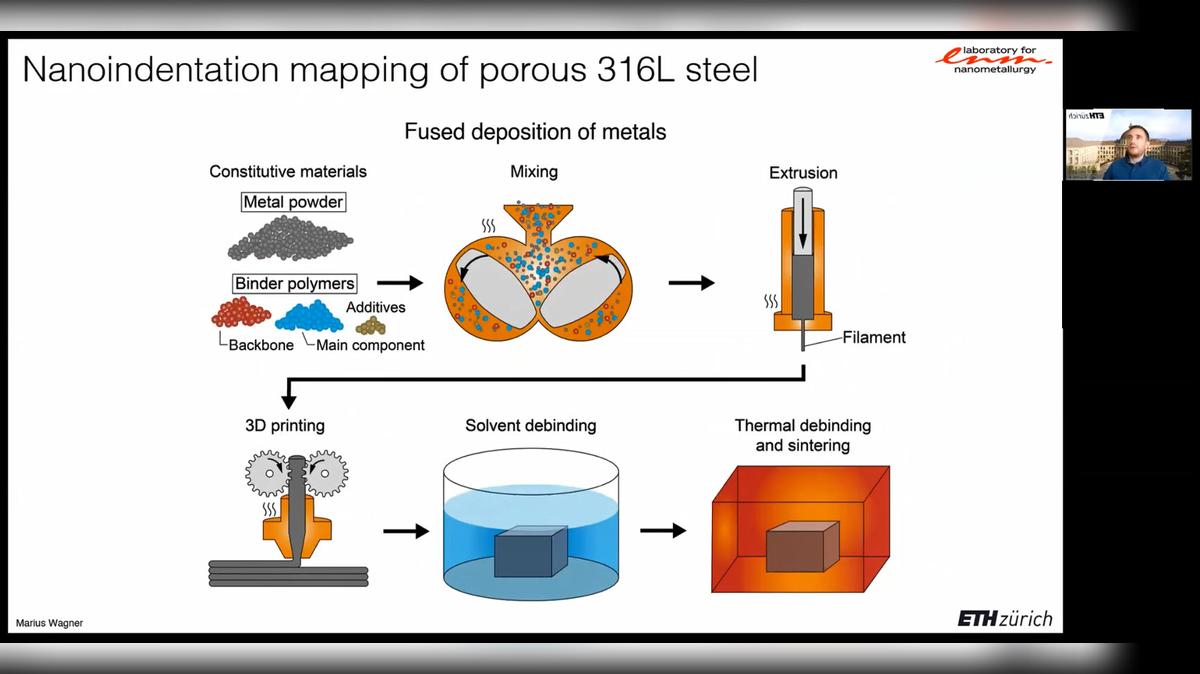

Nanoindentation mapping is a potent tool for characterization of the mechanical properties. In this study we present our latest results on nanoindentation mapping of porous 316L stainless steel, fabricated by fused deposition of metals. Our findings suggest that the spectrum of capabilities of nanoindentation mapping could be extended to characterization of local porosity.

16:43

Technically pure cobalt with a phase transformation temperature of 700 K was investigated by high temperature nanoindentation. From the results of constant indentation strain rate experiments as well as strain rate jump tests the rate controlling deformation mechanisms could be derived. For the low temperature hcp phase from room temperature to 450 K a bcc-like deformation behavior was observed, while from 450 K to 700 K it was found that dislocation cross slip bears plasticity. In the high temperature face centered cubic phase cutting of forest dislocations was identified as the dominating...

06:29

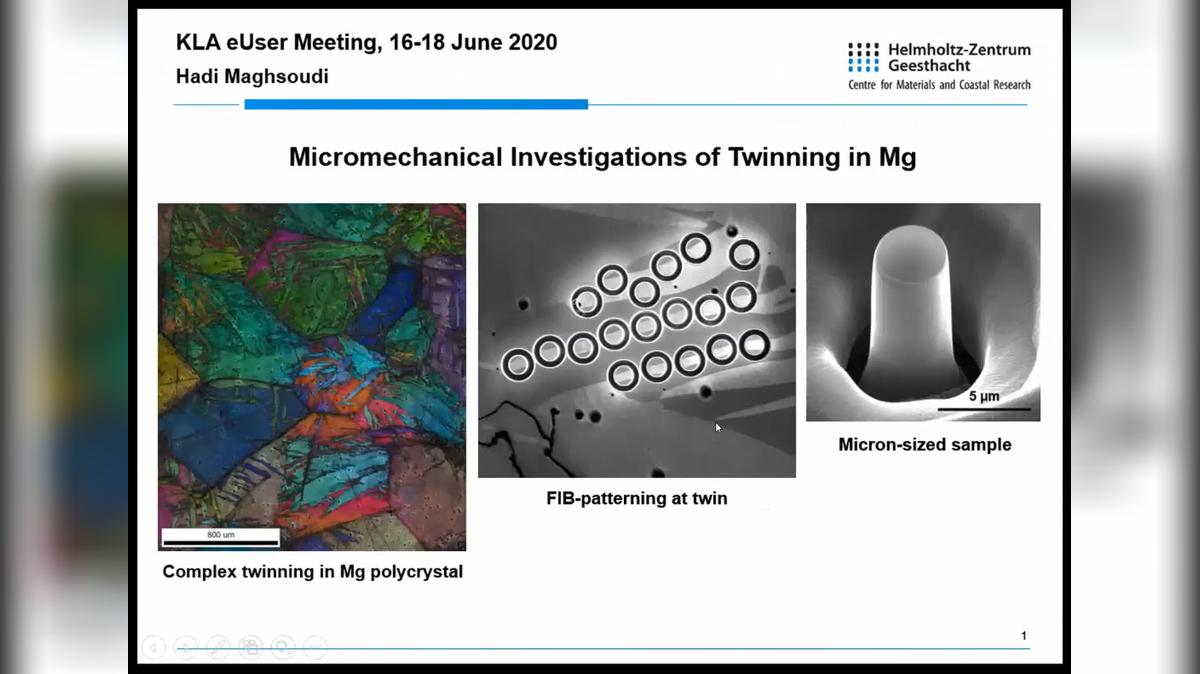

Hadi Maghsoudi provides an excellent presentation on twinning in magnesium materials using pillar compression and other supporting electron microscopy techniques.

12:59

Thermoset matrix composites exhibit severe problems related to their environmentally unfriendly disposal and, therefore, there is a growing need to recycle the fibres and potentially reuse them in new products. The most common technique involves the removal of the polymer matrix at high temperature. The aim of the present work is to assess the evolution of mechanical and nanomechanical properties of single basalt fibres as a function of thermal exposure from the microscale down to the nanoscale, with a view to highlighting the mechanisms responsible for the observed decrease in tensile stre...

06:36

In recent years, nanoindentation systems have been developed which can operate at ever higher temperatures in order to characterize the local mechanical properties and thermally activated mechanisms of high temperature materials such as nickel-based superalloys at their operating temperature. In this work a new ultra-high temperature nanoindentation system for testing at up to 1100 °C will be presented. The system is capable to perform indents from small scale up to large indentation depths due to the combination of a 1 N actuator and a high frame stiffness of > 106 N/m even at 1100 °C. ...

10:06

Hydrogen embrittlement has been of ongoing interest to materials science community and industries over the past several decades. In-situ electrochemical nanoindentation became a versatile tool for probing the impact of electrochemical charging on different materials and technical relevant alloy systems. Besides measuring the classical mechanical properties, such as hardness and Young’s modulus, deeper inside in the acting deformation processes can be gained by advanced nanoindentation testing methods. The so called nanoindentation strain-rate jump tests allow determining the local strain-r...

59:52

3D Surface Roughness Characterization using Zeta-20 optical profiler

Surface roughness characterization can be accomplished through multiple surface metrology measurement techniques. This webinar will introduce some techniques for measuring surface roughness, plus typical methods for quantifying the roughness. In addition, we will explore how 3D topography and advanced quantification methods can be used to deepen your understanding of your surface topography.

23:29

Nanoindentation is typically performed at slow strain rates < ~0.1/s, which precludes it from ballistic applications. Recent years have seen the development of nano-impact testing, which produces much higher deformation rates. However, data from such experiments are challenging to interpret, because the high strain rates are not sustained throughout the experiment and the classical definition of hardness is not applicable.

Constant strain rate nanoindentation yields more meaningful data, albeit at the expense of the deformation velocity. Here, we show that the current strain rate limita...

01:02:45

The first and most enduring application of nanoindentation is the characterization of hard coatings designed for mechanical and chemical protection of an underlying material. Diamond-like carbon is a common coating of this kind, with typical coating thickness being less than 100nm. This session is a live demonstration of nanoindentation with the KLA iNano, optimized for very shallow nanoindentation. Mrs. Hay explains and demonstrates special considerations for shallow nanoindentation, with due consideration for the mechanics of plasticity. With this background, Mrs. Hay demonstrations h...