06:29

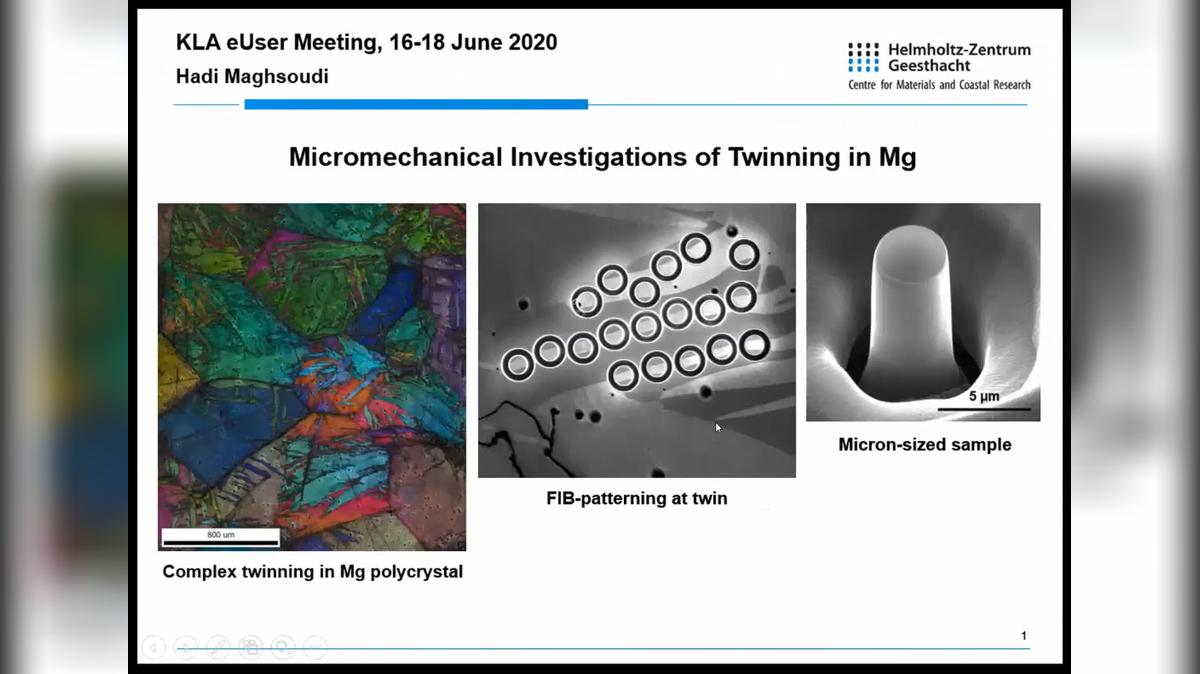

Hadi Maghsoudi provides an excellent presentation on twinning in magnesium materials using pillar compression and other supporting electron microscopy techniques.

12:59

Thermoset matrix composites exhibit severe problems related to their environmentally unfriendly disposal and, therefore, there is a growing need to recycle the fibres and potentially reuse them in new products. The most common technique involves the removal of the polymer matrix at high temperature. The aim of the present work is to assess the evolution of mechanical and nanomechanical properties of single basalt fibres as a function of thermal exposure from the microscale down to the nanoscale, with a view to highlighting the mechanisms responsible for the observed decrease in tensile stre...

01:02:45

The first and most enduring application of nanoindentation is the characterization of hard coatings designed for mechanical and chemical protection of an underlying material. Diamond-like carbon is a common coating of this kind, with typical coating thickness being less than 100nm. This session is a live demonstration of nanoindentation with the KLA iNano, optimized for very shallow nanoindentation. Mrs. Hay explains and demonstrates special considerations for shallow nanoindentation, with due consideration for the mechanics of plasticity. With this background, Mrs. Hay demonstrations h...

01:14:40

Dr. W.C. Oliver and Dr. G.M. Pharr's 1992 publication titled ‘An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments’ is the most cited paper in materials science with over 22,000 citations to date. This webinar provides an opportunity to learn about nanoindentation directly from Dr. Warren Oliver, the co-author of the original paper. In this webinar, Dr. Oliver will provide an introduction to nanoindentation and how it is uniquely positioned to provide deeper insights in the analysis of the process/structure/property r...

26:54

Application and service engineers have leveraged remote operation of the KLA nanoindenters for years. Join us as we share best known methods for remote operation of the instruments and answer your questions.

01:00:57

In digital circuits, materials with low permittivity separate the conducting parts from one another; materials with lower permittivity provide better electrical and magnetic insulation. Continuous reduction in scale drives the optimization problem of lowering the permittivity of the insulator as much as possible, without compromising mechanical integrity, as quantified by the Young’s modulus. (The dielectric constant, k, is a dimensionless expression of permittivity, having been normalized by vacuum permittivity.)

This session is a live demonstration of the nanoindentation technique for m...

01:06:01

Substrate influence is a common problem when using nanoindentation to evaluate the elastic modulus of thin films. In this session, an elastic model for film-substrate interaction is presented which returns accurate film moduli even when substrate influence is substantial. The new model is applied to the interpretation of nanoindentation data on various thin films, including low-k films on silicon.

50:24

How do you know that your nanoindenter is working properly? In this session, Ms. Hay demonstrates the verification process and record keeping for nanoindenters in the KLA contract-test laboratory. Calibration, indent placement, and total performance are all quickly and easily verified using this procedure.

01:01:57

Two nanoindentation calibrations are accomplished by means of indentation experiments on a reference material. These are the load-frame stiffness calibration, which quantifies the expected flexure in the test equipment, and the area-function calibration, which quantifies the precise shape of the indenter. This presentation explains how these calibrations affect nanoindentation analysis, and how the calibrations are accomplished.

01:12:49

Although optical coatings are designed for the control of light (anti-reflective, reflective, splitting, filtering, etc.) it is their mechanical properties which govern longevity. Scratches at any scale lead to excessive absorption of laser energy causing localized thermal stress and ultimate failure. This session is a live demonstration of dynamic nanoindentation with the KLA iMicro nanoindenter to measure Young’s modulus and hardness of optical coatings as a continuous function of penetration depth. Ms. Hay demonstrates sample preparation, instrument configuration, test specification, exe...

52:20

Jennifer Hay unlocks all of the analysis used in dynamic nanoindentation and the continuous stiffness measurement technique. The CSM technique is the greatest advancement in nanoindentation over the last 30 years.