35:51

Dr. Janelle Wharry of Purdue University discusses her group's use of nanoindentation mapping to characterize stress corrosion cracking (SCC) of steel that is used in storing spent nuclear fuel. The research analyzed the nanomechanical properties before and after radiation exposure.

31:48

Dr. Janelle Wharry of Purdue University discusses the use of nanoindentation mapping to understand chloride-induced stress corrosion cracking (SCC) mechanisms in cold spray (CS) coatings used as corrosion mitigation barriers. In addition. Dr. Wharry discusses hardness mapping of grains and along cracks induced by stress corrosion.

20:49

Dominik Weil of KLA Instruments presents fun and unusual nanoindentation applications.

59:27

Nanoindentation is a common technique for measuring the Young’s modulus and hardness of metals. With recent advancements, nanoindentation can now be used to measure the entire stress-strain curve, even within a single metal grain. Join Sr. Application Scientist Jennifer Hay for a discussion of the theory behind this new measurement, and how nanoindentation measurements of force, displacement, and stiffness can be interpreted to arrive at the stress-strain curve.

11:48

Presentation given by Brayer Sousa from Worcester Polytechnic Institute at the USA eUser Meeting in September 2020.

08:56

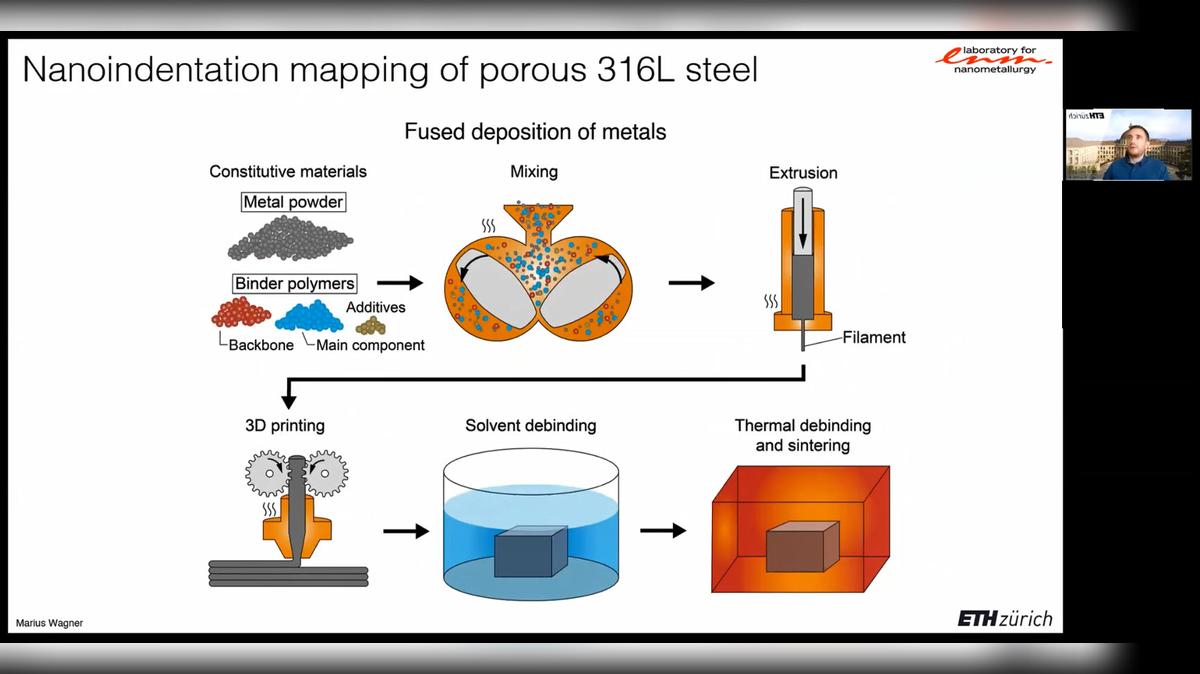

Nanoindentation mapping is a potent tool for characterization of the mechanical properties. In this study we present our latest results on nanoindentation mapping of porous 316L stainless steel, fabricated by fused deposition of metals. Our findings suggest that the spectrum of capabilities of nanoindentation mapping could be extended to characterization of local porosity.

53:38

Low-carbon steels are the first option when designing with steel. They offer good machinability and excellent weldability. To some extent, the strength and ductility can be manipulated by various thermal and mechanical processes, such as working, annealing, and carburization. This session is a live demonstration of standardized nanoindentation with the KLA iMicro nanoindenter to characterize cold-drawn 1018 steel. Ms. Hay demonstrates sample preparation, instrument configuration, test specification, execution and data interpretation.

See the KLA nanoindenters by visiting https://www.kla-ten...